Your DTC pet brand is trapped by a rigid supply chain. You face long lead times1 and high order minimums, making it impossible to react to market trends or launch new designs without huge financial risk.

To thrive, you need a flexible supply chain built on speed and agility. This means partnering with a manufacturer that uses technology for instant design2 and offers low MOQs3 (50 pieces) for rapid, low-risk product testing and launches.

For a modern DTC pet brand, the term "supply chain" can sound intimidating. You might picture massive container ships and complex logistics. But at its core, your supply chain is simply the process that takes your creative idea and turns it into a physical product in your customer's hands. In the past, this process was defined by rigidity and bulk orders. But the rules have changed. Today's market demands speed, variety, and the ability to adapt. Building a flexible supply chain is no longer a luxury; it is the single most important competitive advantage4 you can have heading into 2026 and beyond.

I've worked with countless online brand owners, and I've seen firsthand how an inflexible supply chain can cripple a promising business. It drains cash, stifles creativity, and leaves you unable to compete. This guide will redefine what you should expect from a manufacturing partner. We will break down the three essential pillars of a truly flexible supply chain and show you how to build one that makes your brand more profitable, more creative, and more resilient.

Is Your Supply Chain Too Slow for Today's Trends?

You see a new trend taking off, but your current manufacturer takes weeks just to create a sample. By the time you can launch, the trend is over, and you've missed the opportunity completely.

This problem isn't about production; it's about the speed from idea to approval. A flexible partner eliminates this delay with technology, allowing you to create a Mockup in seconds5 and receive a physical Sample in 3 Days6.

The speed of online culture is relentless. A pattern, color, or style can explode in popularity on social media overnight. For a DTC brand, the ability to tap into these micro-trends is a massive opportunity to drive sales and attract new customers. However, a traditional supply chain is the enemy of this kind of speed. It is built on a slow, linear process: you send an email with your idea, wait for a designer to create a flat 2D proof, go back and forth with revisions, and then wait weeks for a physical sample to arrive from overseas. This entire process can take over a month. This delay is a critical failure point in a modern supply chain7. It forces you to watch from the sidelines as more agile competitors capture the market.

Building a Supply Chain for "Right Now"

A truly flexible supply chain8 must be built for immediate action. This requires a partner who has invested in technology to compress the design and sampling timeline from weeks into days.

-

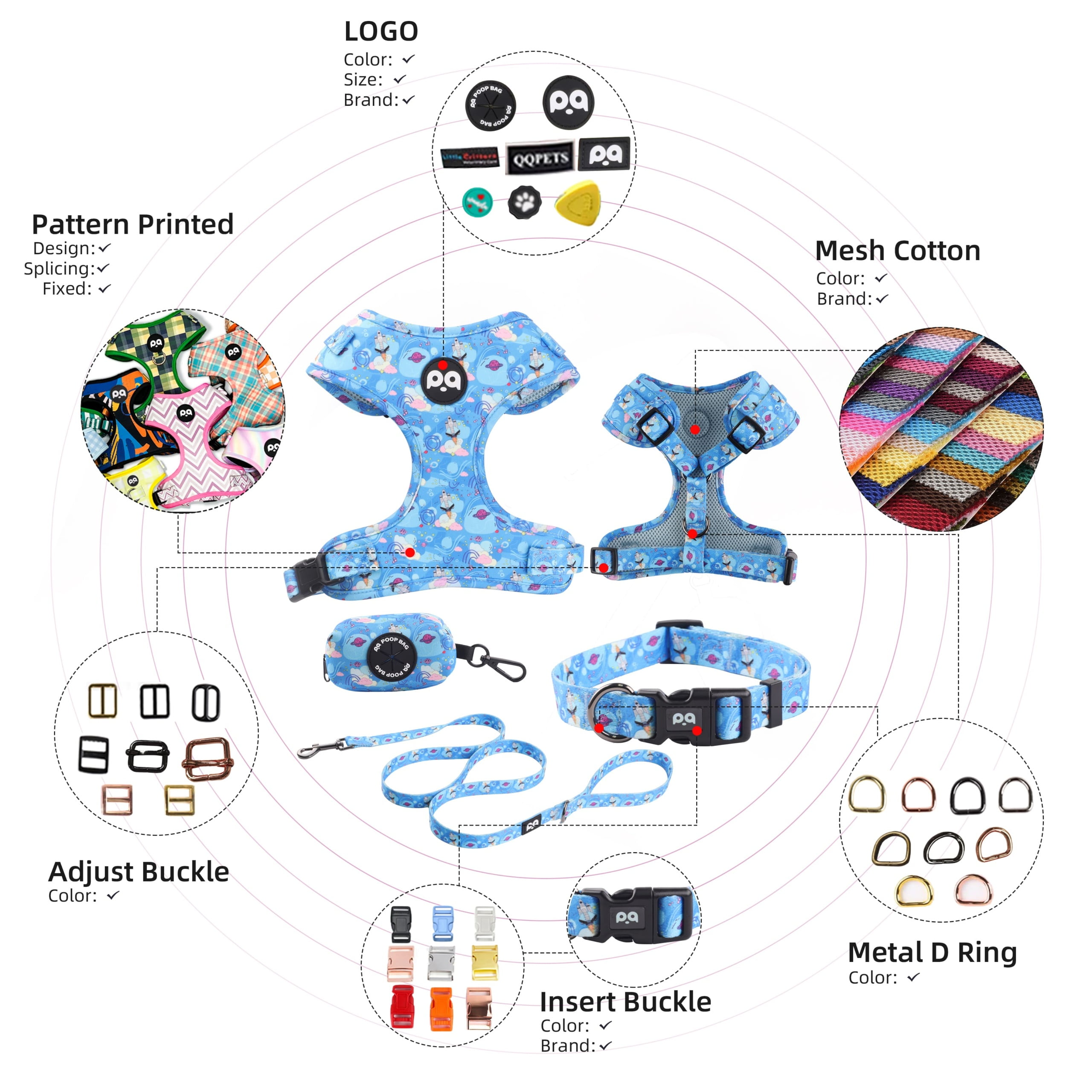

Tertiary Heading: The Power of Instant Visualization The biggest delay has always been visualizing the final product. We solved this by creating a free, web-based 3D customization system. This tool puts you in complete control. You can upload your unique Vlastní vzory, position your logo, and see a photorealistic 3D model of your product in real-time. There is no more guessing or waiting. You see exactly what you will get, instantly.

-

Tertiary Heading: From Screen to Your Hands in 72 Hours Once you approve your digital design, our rapid prototyping system takes over. We can produce and ship a high-quality physical sample of your unique creation in just 3 days. This means you can go from a fleeting idea to holding the actual product in less than a week.

| Supply Chain Stage | Traditional Model (Inflexible) | Modern Model (Flexible) |

|---|---|---|

| Design Visualization | 2-5 Day Wait for a 2D Proof | Instant 3D Mockup |

| Design Revisions | 1-2 Days Per Revision | Instant, User-Controlled |

| Sample Production | 2-4 Weeks | 3 Days |

| Competitive Edge | Reactive and Slow | Proactive and Fast |

This speed is the first pillar of a flexible supply chain, giving you the power to act on trends the moment they emerge.

Are High MOQs Draining Your DTC Brand's Cash Flow?

You want to offer your customers a wide variety of fresh, exciting designs. But traditional manufacturers demand huge Minimum Order Quantities (MOQs), forcing you to bet your entire budget on just one or two patterns.

This isn't just an inventory problem; it's a cash flow crisis9. A flexible supply chain is built on "lightweight customization10," which means a low MOQ of just 50 pieces per design, allowing you to test many ideas with minimal financial risk.

Cash flow is the oxygen for your e-commerce business. Every dollar that is tied up in unsold inventory is a dollar that cannot be used for marketing, developing new products, or even paying yourself. This is the fundamental danger of a supply chain built around high MOQs. It forces a small, agile brand to behave like a massive, slow-moving retailer. You are forced to make a huge financial gamble on a design that you think will be popular. If you're wrong, you're left with a mountain of dead stock and a serious hole in your bank account. This financial risk is a major source of stress for brand owners and the single biggest barrier to creative experimentation11 and growth. A flexible supply chain must protect your cash flow, not threaten it.

The Financial Flexibility of Small-Batch Production

The ability to order in small batches is the second, crucial pillar of a flexible supply chain. It fundamentally changes how you manage inventory and launch new products.

-

Tertiary Heading: De-Risking Product Launches An MOQ of just 50 pieces per size and pattern transforms a high-stakes gamble into a series of low-risk experiments. Instead of investing $5,000 into 1,000 units of one design, you can now invest that same amount into launching 10 different designs with 100 units each. This diversification dramatically increases your chances of finding a winning product.

-

Tertiary Heading: Data-Driven Reordering This model allows you to use your customers' behavior as your primary source of business intelligence. Launch your diverse collection and let the sales data tell you what's working. The designs that sell out quickly are your proven winners. You can then confidently place larger, more profitable reorders for those specific items. Your inventory decisions are no longer based on hope; they are based on hard evidence. To start building a more financially sound inventory strategy, contact our team.

Does Your Manufacturer Guarantee Quality and Consistency at Scale?

You've found a supplier, but you're constantly worried. Will the quality of your 1000th collar be as good as the first sample? Will a sudden delay cause you to go out of stock on your bestseller?

This uncertainty undermines your entire operation. The third pillar of a flexible supply chain is reliability, which comes from verifiable systems like ISO 9001 certification12, stable výrobní kapacita13, and professional support.

A supply chain can be fast and financially efficient, but if it's not reliable, it will eventually fail. Reliability means two things: consistent product quality and predictable delivery times. Inconsistent quality can destroy your brand's reputation with a single bad batch. Unpredictable deliveries can lead to stockouts on your most popular items, resulting in lost sales and frustrated customers who may go to a competitor. Many brand owners think that these risks are just an unavoidable part of manufacturing. However, a truly professional partner builds their operations around systems and processes designed to eliminate this uncertainty. A flexible supply chain must also be a stable one you can depend on as you grow.

The Foundation of a Dependable Partnership

Reliability isn't a matter of luck; it's the result of deliberate investment in quality management and operational infrastructure.

-

Tertiary Heading: Verifiable Quality You Can Trust Don't accept vague promises of "good quality." Demand objective proof. We have built our entire production process around the ISO 9001 quality management system14. This international certification is awarded by an independent body and verifies that our procedures for material inspection, production, and final testing meet a global standard of excellence. This is your assurance that every order will meet the exact same high-quality specifications.

-

Tertiary Heading: Production Stability for Seamless Growth Consistent delivery schedules depend on a stable production environment. We operate three dedicated production lines, which gives us the capacity and flexibility to manage orders efficiently and avoid the bottlenecks that cause delays at smaller facilities. This operational strength is supported by a customer service team15 trained specifically for the needs of global DTC brands, providing clear communication and expert support throughout the entire process. You can learn more about our factory and our commitment to quality on our homepage.

Závěr

Building a flexible supply chain is your ultimate advantage. By prioritizing a partner who delivers speed, financial agility, and verifiable reliability, you can create a DTC pet brand that is more creative, profitable, and ready for the future.

---Discover strategies to minimize lead times and improve your product launch speed. ↩

Explore the role of technology in streamlining the design process for faster results. ↩

Find out how low MOQs can help you test new products with less financial risk. ↩

Understand the factors that can give your brand a competitive edge in the market. ↩

Learn about innovative tools that allow for quick visualization of product designs. ↩

Discover the processes that enable rapid sample production and delivery. ↩

Explore the characteristics of a modern supply chain and its importance for brands. ↩

Explore how a flexible supply chain can enhance your brand's agility and responsiveness to market trends. ↩

Identify the warning signs of cash flow issues and how to address them effectively. ↩

Learn how lightweight customization can enhance product variety without financial strain. ↩

Discover how creative experimentation can drive innovation and growth. ↩

Learn about the significance of ISO 9001 certification in ensuring product quality. ↩

Discover the impact of production capacity on your supply chain's performance. ↩

Understand the components of a quality management system and its benefits. ↩

Learn about the role of customer service in supporting supply chain success. ↩