The DTC pet market is more crowded than ever. Relying on an old, rigid supply chain makes you slow and vulnerable, leaving your brand unable to compete with the speed of modern trends.

A flexible supply chain is the core competency for future DTC success because it allows you to launch new products quickly, test ideas with minimal financial risk1, and respond instantly to market data2. It replaces slow, risky bets with fast, agile, and profitable decisions.

The rules for building a successful direct-to-consumer (DTC) brand have changed. A few years ago, having a good product and a decent website was enough. But as we look toward 2026, the market is saturated with "good" products. Your competitors are everywhere. The cost of ads is rising, and customer attention is harder to win than ever. In this new environment, the brand that wins is not the biggest or the one with the most funding. The brand that wins is the one that can move the fastest.

Your ability to adapt, innovate, and respond to your customers is now your most critical advantage. And this ability is not determined by your marketing budget; it's determined by the flexibility of your supply chain. A slow, rigid supply chain is an anchor that will sink your brand. A fast, flexible one is the engine that will drive your growth. As a customization expert3 for global online brands, I'll show you exactly what this new model of partnership looks like and how it will become your core competency.

How Can You Launch New Products Faster Than Your Competitors?

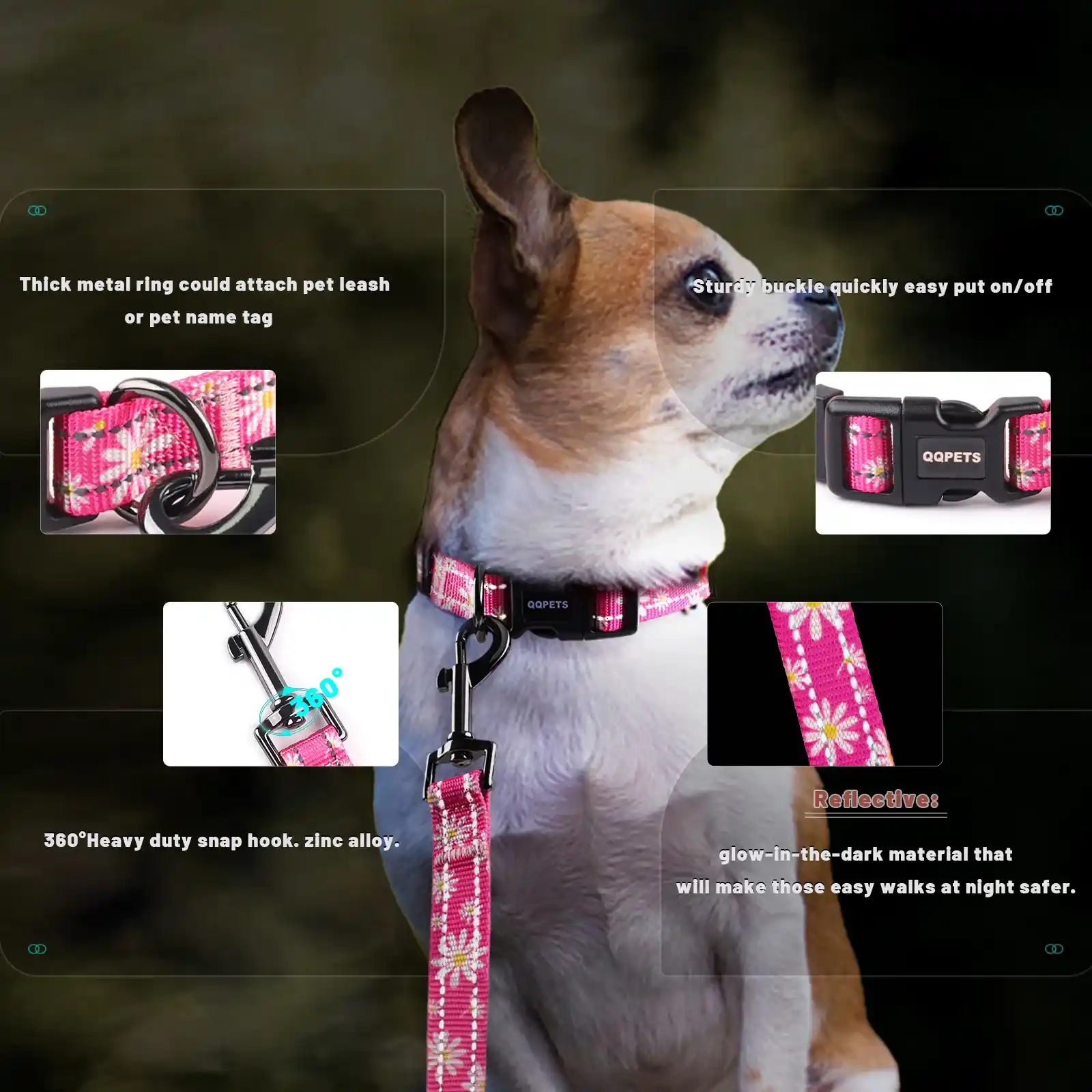

You have a brilliant idea for a new dog collar pattern, but you know the traditional process takes months. By the time your product is ready, the trend will be over and your competitors will have beaten you to it.

This speed problem is solved with technology, not just better communication. A modern manufacturing partner provides an integrated digital system where you get a mockup in seconds4 and a physical sample in 3 days.

In the world of social media, trends move at the speed of a viral TikTok video. The ability to launch a product that taps into a current cultural moment is a superpower. However, the old manufacturing model is the enemy of speed. It involves a long and frustrating chain of emails, flat design files, Pantone color arguments, and weeks of waiting for a physical sample that might not even be correct. This process is a momentum killer. It forces you to operate on a 6-month timeline in a 6-day world. A flexible supply chain flips this entire model on its head by prioritizing rapid product development.

The New vs. Old Way of Product Creation

Your brand's lifeblood is newness, and for pet accessories5, a unique Custom Pattern is a new product. A truly flexible supply chain uses technology to make the creation of these new products virtually instantaneous.

-

Tertiary Heading: The Traditional Bottleneck The old method relies on a slow, linear process. Each step is a potential point of failure and delay, stretching the time from idea to marketable product over several months.

-

Tertiary Heading: The Flexible Technology Stack We replaced this entire clumsy process with a powerful digital system. Our [3D customization platform](https://londondynamics.com/blog/customization/what-is-3d-product-customization-an-introductory-guide/)6 lets you be the creator. You can upload your own designs or use our AI-powered tools to generate new patterns, see them on a photorealistic 3D model instantly, and get a physical sample in your hands in days.

| Feature | The Old, Rigid Way | The New, Flexible Way (Our System) |

|---|---|---|

| Design Time | Weeks of emails | Seconds on a 3D platform |

| Sample Time | 3-4 Weeks | 3 Days |

| Risk of Error | High (miscommunication) | Low (visual confirmation) |

| Time to Market | 2-3 Months | 1-2 Weeks |

This is not just a minor improvement; it is a fundamental shift that allows you to operate at the true speed of e-commerce.

How Can You Test the Market Without Betting Your Entire Budget?

You want to expand your product line, but the high Minimum Order Quantities7 (MOQs) from most factories are terrifying. You cannot afford to tie up thousands of dollars in a single design that might not sell.

This is where a flexible supply chain creates financial freedom. A modern partner built for DTC brands will offer "lightweight customization8," allowing you to order in micro-batches as low as 50 pieces per design.

For a growing DTC brand, cash flow is everything. It's the money you need for marketing, for inventory, and for paying yourself. The traditional manufacturing model, with its demand for high MOQs, is designed for giant retailers, and it is toxic to your cash flow. It forces you into a high-stakes gambling situation where you bet your entire budget on a single product based on guesswork. If you guess wrong, your capital is trapped in dead stock, and your business can be crippled. A flexible supply chain demolishes this risk by changing the fundamental economic equation of production.

The Strategy of Lightweight Customization

A flexible supply chain isn't just about getting products faster; it's about de-risking your growth. The ability to produce in small batches is the key to building a resilient, data-driven brand9.

-

Tertiary Heading: From Guesswork to Data Instead of ordering 2,000 units of one design you hope will sell, you can now order 100 units each of 20 different designs. You can launch them all on your store and see what your customers actually buy. The market tells you what to reorder, eliminating guesswork.

-

Tertiary Heading: Building a Broader Catalog This low MOQ approach allows you to offer a much wider variety of products. You can have seasonal collections, limited edition drops, and collaborations10 without the massive upfront investment. This makes your brand more interesting and gives customers more reasons to come back.

| Aspect | High MOQ (Rigid Supply Chain) | Low MOQ (Flexible Supply Chain11) |

|---|---|---|

| Initial Investment | High Risk, All on one product | Low Risk, Spread across many |

| Decision Making | Based on Guesswork | Based on Real Sales Data |

| Inventory Health | Risk of Dead Stock | Lean and Profitable |

| Brand Agility | Slow and Clumsy | Fast and Responsive |

This is the financial core of a flexible supply chain. As experts in this model, we've seen countless brands accelerate their growth by adopting this strategy. You can contact us to learn how to implement it.

How Do You Maintain Quality and Reliability When Moving So Fast?

You're excited by the idea of speed and flexibility, but a part of you is worried. How can you be sure that moving this quickly doesn't mean you're sacrificing quality, reliability, and consistency?

This is a critical question. True flexibility is impossible without a foundation of trust and reliability. A top-tier flexible partner combines speed with robust, certified quality systems12 and stable, predictable production capacity.

It's easy to assume that "fast" and "flexible" are just other words for "cheap" and "unreliable." In the past, this was often true. Many factories that offered low MOQs were small, unorganized workshops with inconsistent output. But the modern, flexible supply chain is different. It is a highly sophisticated system that leverages technology and process management to deliver both speed and world-class quality simultaneously. The key is to find a partner who has not just adopted flexible quantities, but has also invested heavily in the backend systems to support that flexibility with unwavering reliability.

The Pillars of Reliable Flexibility

A truly flexible and reliable supply chain rests on three essential pillars. When you are vetting a potential partner, you must ensure they can deliver on all three.

-

Tertiary Heading: Verifiable Quality Systems Speed without quality is worthless. Your partner must have internationally recognized certifications, like ISO 9001. This is non-negotiable. It's external proof that their processes are documented, controlled, and audited for consistency. It is the bedrock of trust.

-

Tertiary Heading: Stable Production Capacity What happens when you launch 20 test designs and one of them goes viral? Your partner must have the production depth to scale with your success. A factory with multiple dedicated production lines can handle your small test orders and your large re-orders with the same stable lead times.

-

Tertiary Heading: Professional Human Support Technology is the enabler, but you are still partnering with people. A reliable partner has a dedicated, professional customer service team that can solve problems quickly. Clear, proactive communication is the glue that holds a fast-moving partnership together.

Flexibility is not chaos. It is highly controlled, system-driven speed, built on a foundation of absolute reliability.

Conclusion

In 2026, the winning DTC pet brands will be the most agile. A flexible supply chain is no longer a "nice to have"—it is your core competitive competency13, and choosing the right partner is your most important strategic decision.

Discover methods to reduce financial risk when testing new product ideas. ↩

Understand the importance of market data in making informed product decisions. ↩

Find out how a customization expert can enhance your product offerings. ↩

Learn about technologies that enable quick product mockups for faster development. ↩

Stay updated on the latest trends in pet accessories to enhance your product line. ↩

Discover how 3D customization platforms can revolutionize product design. ↩

Understand how MOQs affect your production strategy and cash flow. ↩

Explore the concept of lightweight customization and its benefits for DTC brands. ↩

Learn how to leverage data to make informed decisions for your brand. ↩

Discover how collaborations can expand your product range and attract customers. ↩

Explore how a flexible supply chain can enhance your DTC brand's agility and responsiveness to market trends. ↩

Discover best practices for ensuring quality in a fast-paced production environment. ↩

Understand the importance of identifying and developing core competencies for success. ↩